### 🛠️ **Techniques for Safe & Efficient Concrete Support Removal**

#### 1. **Assessment & Planning**

- **Inspect the structure** to determine load-bearing elements and reinforcement (e.g., rebar).

- Use structural drawings or consult an engineer to avoid compromising stability.

- Identify utilities (electrical, plumbing) before cutting or breaking.

#### 2. **Pre-Cutting & Sectioning**

- Use a **concrete saw with a diamond blade** to cut supports into manageable sections.

- Pre-cutting reduces vibration and prevents uncontrolled cracking.

#### 3. **Controlled Demolition Tools**

- **Jackhammers**: Ideal for breaking up smaller or thinner supports.

- **Hydraulic splitters or breakers**: Efficient for thicker, reinforced concrete.

- **Robotic demolition machines**: Useful in confined or hazardous areas for precision and safety.

#### 4. **Support Shoring**

- Before removing any structural support, install **temporary shoring** to redistribute loads.

- Use adjustable steel props or scaffolding systems rated for the expected load.

#### 5. **Manual Removal**

- For smaller jobs, use **sledgehammers, pry bars, and chisels**.

- Always start from the top and work downward to maintain control.

### 🧯 **Safety Measures**

- **Wear PPE**: Hard hats, gloves, goggles, steel-toe boots, and hearing protection.

- **Dust control**: Use water spray or dust extractors to minimize airborne particles.

- **Debris management**: Clear broken concrete regularly to prevent tripping hazards.

- **Team communication**: Use hand signals or radios in noisy environments.

### ♻️ **Debris Disposal & Recycling**

- Sort and transport concrete debris to **recycling centers** where it can be crushed and reused.

- Check local regulations for disposal requirements.

*********************************************************************************** Here’s a detailed 2500-word article on:

How to Accurately Prepare for Concrete Machine Support Removal

Introduction

Concrete plays a crucial role in the modern construction industry. Its strength and durability make it a preferred material for a wide range of applications, from residential buildings to massive infrastructure projects like bridges and dams. However, behind every successful concrete structure lies a meticulous process of formwork installation and, more importantly, formwork removal or machine support removal. This step is critical because premature or improper removal can result in serious structural failures.

Machine support removal refers to the process of taking away the temporary supports, such as formwork, props, shoring, and falsework, used during concrete curing and setting. Doing this accurately ensures the structural integrity of the concrete while avoiding damage and safety hazards on site.

This article offers an in-depth guide on how to accurately prepare for concrete machine support removal, ensuring safety, structural performance, and adherence to engineering standards.

1. Understanding the Importance of Machine Support in Concrete Structures

Before delving into the preparation process, it’s vital to understand why temporary supports are needed in the first place.

1.1 Purpose of Machine Supports

-

To maintain shape and alignment: Supports ensure the concrete remains in its intended position during the curing phase.

-

To bear loads temporarily: Fresh concrete has almost no strength after placement. The supports hold the weight until sufficient strength develops.

-

To ensure safety: Prevents sudden collapse, cracking, or deformation during the early stages of setting.

1.2 Risks of Early Support Removal

Removing supports too early can cause:

Therefore, understanding the right time and method for machine support removal is essential.

2. Factors Influencing Support Removal Timing

The timing of support removal depends on several factors, each of which must be assessed before proceeding.

2.1 Concrete Strength Gain

Concrete doesn’t achieve full strength immediately. Typically, it gains:

-

30% strength in 3 days

-

60-70% in 7 days

-

90% in 28 days

Key Point: Always verify compressive strength through laboratory tests before proceeding.

2.2 Ambient Temperature and Curing Conditions

2.3 Type of Cement Used

-

Ordinary Portland Cement (OPC): Standard strength gain

-

Rapid Hardening Cement: Faster gain

-

Pozzolanic Cement: Slower gain

2.4 Load Duration and Distribution

Different structural elements bear different loads:

2.5 Structural Element Size and Design

3. Pre-Removal Inspection Checklist

Before starting support removal, a comprehensive site inspection is mandatory.

3.1 Structural Assessment

3.2 Concrete Strength Testing

-

Conduct cube or cylinder strength tests from lab samples

-

Use rebound hammer or ultrasonic pulse velocity tests for quick, non-destructive testing (NDT) on-site

3.3 Review Structural Drawings and Specifications

3.4 Load Redistribution Checks

Before removing any support, check that the structure can redistribute loads without failure.

4. Communication and Safety Planning

Support removal is a risky activity that requires clear communication and safety protocols.

4.1 Team Briefing

-

Conduct pre-removal meetings

-

Define roles and responsibilities

-

Highlight emergency procedures

4.2 Risk Assessment

-

Prepare a Job Hazard Analysis (JHA) or Risk Assessment Method Statement (RAMS)

-

Identify fall risks, collapse hazards, and equipment safety concerns

4.3 Personal Protective Equipment (PPE)

Ensure all workers wear:

4.4 Tools and Equipment Check

-

Ensure lifting tools, jacks, or mechanical devices are in good condition

-

Inspect scaffolding and working platforms

5. Step-by-Step Process for Safe Support Removal

The following procedural steps provide a systematic approach to accurate and safe concrete support removal.

Step 1: Obtain Approval from Structural Engineer

No support should be removed without written approval.

Step 2: Sequence the Removal Process

Support should be removed in a reverse sequence of erection, starting from the last placed element.

For example:

Step 3: Partial Stripping

-

Initially remove only non-load-bearing elements like side forms.

-

Gradually remove main load-bearing supports.

-

Retain back-propping if necessary.

Step 4: Monitor Deflection and Movement

Use deflection gauges and laser levels to measure any immediate sagging or misalignment.

Step 5: Gradual Load Transfer

If mechanical props are used, lower them incrementally to allow gradual load transfer onto the concrete.

Step 6: Post-removal Inspection

Once supports are fully removed:

-

Check surface quality

-

Inspect for cracks, honeycombing, or deflection

-

Report findings to the site engineer

6. Recommended Timeframes for Support Removal (General Guidelines)

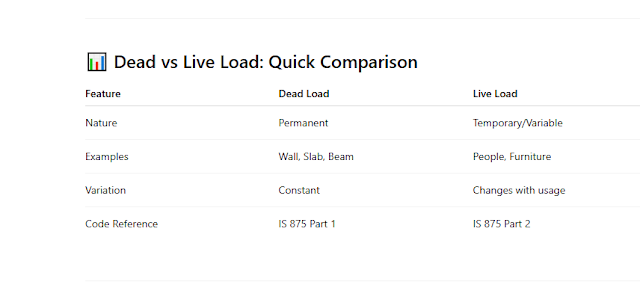

While actual removal times depend on site conditions, the following table offers typical guidelines (based on IS 456:2000 and ACI 347R):

| Structural Member |

Minimum Time Before Support Removal |

| Vertical sides of beams and columns |

16-24 hours |

| Slab soffits (props to remain) |

3 days |

| Beam soffits (props to remain) |

7 days |

| Props for slabs (under 4.5m span) |

7 days |

| Props for slabs (over 4.5m span) |

14 days |

| Props for beams (up to 6m span) |

14 days |

| Props for beams (over 6m span) |

21 days |

Note: These are indicative only. Actual timeframes should follow site-specific structural engineer recommendations.

7. Advanced Monitoring Techniques

For critical structures, adopt advanced technologies to enhance safety during support removal.

7.1 Embedded Sensors

7.2 Load Cells on Props

7.3 Drones and Laser Scanning

8. Common Mistakes to Avoid During Machine Support Removal

8.1 Ignoring Strength Test Results

Proceeding with removal just because "enough days have passed" without verifying concrete strength is dangerous.

8.2 Removing Supports Too Quickly

Rapid removal creates sudden load transfer, leading to cracks or collapses.

8.3 Lack of Communication

Failure to inform all teams on site can lead to accidents.

8.4 Overloading the Structure Immediately After Removal

Allow adequate time before placing construction loads like brickwork, partitions, or storage materials.

8.5 Non-sequential Removal

Removing supports randomly disturbs load paths and compromises stability.

9. Case Studies of Support Removal Failures

Understanding past failures can reinforce the importance of accurate preparation.

Case 1: Bridge Collapse Due to Premature Support Removal

In 2018, a pedestrian bridge in a metropolitan city collapsed because the temporary supports were removed before the concrete reached design strength. The investigation revealed:

Case 2: Slab Failure in High-rise Building

A high-rise building suffered a partial slab collapse due to early formwork removal coupled with overloaded equipment stored on top. This highlights the need for load control post-removal.

10. Best Practices for Long-Term Safety

-

Document Every Step: Keep detailed records of removal dates, strength test results, and engineer approvals.

-

Train Workers: Conduct periodic training sessions on formwork erection and removal procedures.

-

Use Technology: Adopt modern monitoring systems for large projects.

-

Engage Experts: Always consult structural engineers before making critical decisions.

Conclusion

Concrete machine support removal is more than just dismantling temporary structures. It’s a highly technical and risk-sensitive process that demands planning, testing, communication, and strict supervision.

By following the guidelines outlined above, construction teams can ensure:

At the end of the day, accuracy in preparation for machine support removal is a crucial pillar of successful concrete construction.

Channel Shoutout for Your YouTube Script:

"For more expert tips on civil engineering and site safety practices, don’t forget to like, share, and subscribe to Engineers India Solution! Stay tuned for more real-world construction site knowledge and engineering insights!"

### 🛠️ **सुरक्षित और कुशल कंक्रीट सपोर्ट हटाने की तकनीकें**

#### 1. **मूल्यांकन और योजना**

- **लोड-असर करने वाले तत्वों और सुदृढ़ीकरण (जैसे, रीबर) को निर्धारित करने के लिए संरचना का निरीक्षण करें।

- स्थिरता से समझौता करने से बचने के लिए संरचनात्मक चित्रों का उपयोग करें या किसी इंजीनियर से परामर्श लें।

- काटने या तोड़ने से पहले उपयोगिताओं (विद्युत, प्लंबिंग) की पहचान करें।

### 2. **प्री-कटिंग और सेक्शनिंग**

- समर्थन को प्रबंधनीय खंडों में काटने के लिए **हीरे के ब्लेड वाली कंक्रीट आरी** का उपयोग करें।

- प्री-कटिंग कंपन को कम करती है और अनियंत्रित दरार को रोकती है।

### 3. **नियंत्रित विध्वंस उपकरण**

- **जैकहैमर**: छोटे या पतले समर्थन को तोड़ने के लिए आदर्श।

- **हाइड्रोलिक स्प्लिटर या ब्रेकर**: मोटे, प्रबलित कंक्रीट के लिए कुशल।

- **रोबोटिक विध्वंस मशीनें**: सटीकता और सुरक्षा के लिए सीमित या खतरनाक क्षेत्रों में उपयोगी।

#### 4. **सपोर्ट शोरिंग**

- किसी भी संरचनात्मक समर्थन को हटाने से पहले, लोड को फिर से वितरित करने के लिए **अस्थायी शोरिंग** स्थापित करें।

- अपेक्षित लोड के लिए रेटेड समायोज्य स्टील प्रॉप्स या मचान सिस्टम का उपयोग करें।

#### 5. **मैनुअल रिमूवल**

- छोटे कामों के लिए, **स्लेजहैमर, प्राइ बार और छेनी** का उपयोग करें।

- हमेशा ऊपर से शुरू करें और नियंत्रण बनाए रखने के लिए नीचे की ओर काम करें।

### 🧯 **सुरक्षा उपाय**

- **पीपीई पहनें**: हार्ड हैट, दस्ताने, चश्मा, स्टील-टो बूट और सुनने की सुरक्षा।

- **धूल नियंत्रण**: हवा में मौजूद कणों को कम करने के लिए पानी के स्प्रे या धूल निकालने वाले यंत्रों का उपयोग करें।

- **मलबे का प्रबंधन**: फिसलने के खतरों को रोकने के लिए नियमित रूप से टूटे हुए कंक्रीट को साफ करें।

- **टीम संचार**: शोरगुल वाले वातावरण में हाथ के संकेतों या रेडियो का उपयोग करें।

### ♻️ **मलबे का निपटान और पुनर्चक्रण**

- कंक्रीट के मलबे को छांटकर **पुनर्चक्रण केंद्रों** तक पहुँचाएँ जहाँ इसे कुचला जा सके और फिर से इस्तेमाल किया जा सके।

- निपटान आवश्यकताओं के लिए स्थानीय नियमों की जाँच करें।

***********************************************************************************

कंक्रीट मशीन सपोर्ट हटाने के लिए सटीक रूप से तैयारी कैसे करें

परिचय

कंक्रीट आधुनिक निर्माण उद्योग में एक महत्वपूर्ण भूमिका निभाता है। इसकी मजबूती और टिकाऊपन इसे आवासीय भवनों से लेकर पुलों और बाँधों जैसी विशाल बुनियादी ढाँचा परियोजनाओं तक, कई तरह के अनुप्रयोगों के लिए एक पसंदीदा सामग्री बनाता है। हालांकि, हर सफल कंक्रीट संरचना के पीछे फॉर्मवर्क इंस्टॉलेशन और उससे भी महत्वपूर्ण रूप से फॉर्मवर्क हटाने या मशीन सपोर्ट हटाने की एक सावधानीपूर्वक प्रक्रिया होती है। यह कदम महत्वपूर्ण है क्योंकि समय से पहले या अनुचित तरीके से हटाने से गंभीर संरचनात्मक विफलताएं हो सकती हैं।

मशीन सपोर्ट हटाने से तात्पर्य कंक्रीट के इलाज और सेटिंग के दौरान उपयोग किए जाने वाले अस्थायी सपोर्ट जैसे फॉर्मवर्क, प्रॉप्स, शोरिंग और फाल्सवर्क को हटाने की प्रक्रिया से है। ऐसा करने से साइट पर नुकसान और सुरक्षा खतरों से बचते हुए कंक्रीट की संरचनात्मक अखंडता सुनिश्चित होती है।

यह लेख कंक्रीट मशीन सपोर्ट हटाने के लिए सटीक रूप से तैयारी करने, सुरक्षा, संरचनात्मक प्रदर्शन और इंजीनियरिंग मानकों का पालन करने के तरीके पर एक गहन मार्गदर्शिका प्रदान करता है।

1. कंक्रीट संरचनाओं में मशीन सपोर्ट के महत्व को समझना

तैयारी प्रक्रिया में जाने से पहले, यह समझना महत्वपूर्ण है कि सबसे पहले अस्थायी सपोर्ट की आवश्यकता क्यों है।

1.1 मशीन सपोर्ट का उद्देश्य

आकार और संरेखण बनाए रखना: सपोर्ट सुनिश्चित करते हैं कि इलाज के चरण के दौरान कंक्रीट अपनी इच्छित स्थिति में रहे।

अस्थायी रूप से भार सहन करना: ताजा कंक्रीट में प्लेसमेंट के बाद लगभग कोई ताकत नहीं होती है। सपोर्ट तब तक वजन को संभाले रखते हैं जब तक कि पर्याप्त ताकत विकसित न हो जाए।

सुरक्षा सुनिश्चित करने के लिए: सेटिंग के शुरुआती चरणों के दौरान अचानक ढहने, टूटने या विरूपण को रोकता है।

1.2 समय से पहले सपोर्ट हटाने के जोखिम

बहुत जल्दी सपोर्ट हटाने से निम्न हो सकते हैं:

कंक्रीट का विक्षेपण

दरार या क्रेज़िंग

संरचनात्मक विफलता पूरी तरह से

कर्मचारियों और उपकरणों के लिए सुरक्षा जोखिम

इसलिए, मशीन सपोर्ट हटाने के लिए सही समय और विधि को समझना आवश्यक है।

2. सपोर्ट हटाने के समय को प्रभावित करने वाले कारक

सपोर्ट हटाने का समय कई कारकों पर निर्भर करता है, जिनमें से प्रत्येक का आगे बढ़ने से पहले मूल्यांकन किया जाना चाहिए।

2.1 कंक्रीट की ताकत में वृद्धि

कंक्रीट तुरंत पूरी ताकत हासिल नहीं करता है। आम तौर पर, यह हासिल करता है:

3 दिनों में 30% ताकत

7 दिनों में 60-70%

28 दिनों में 90%

मुख्य बिंदु: आगे बढ़ने से पहले हमेशा प्रयोगशाला परीक्षणों के माध्यम से संपीड़न शक्ति की पुष्टि करें।

2.2 परिवेश का तापमान और क्योरिंग की स्थिति

ठंडा मौसम ताकत बढ़ाने में देरी करता है

गर्म मौसम क्योरिंग को तेज़ करता है लेकिन अगर ठीक से प्रबंधित न किया जाए तो सतह पर दरारें पड़ सकती हैं

2.3 इस्तेमाल किए जाने वाले सीमेंट का प्रकार

साधारण पोर्टलैंड सीमेंट (OPC): मानक ताकत बढ़ाने वाला

तेज़ सख्त सीमेंट: तेज़ लाभ

पॉज़ोलानिक सीमेंट: धीमी वृद्धि

2.4 लोड अवधि और वितरण

विभिन्न संरचनात्मक तत्व अलग-अलग भार सहन करते हैं:

स्लैब और बीम: आमतौर पर लंबे समय तक समर्थन अवधि की आवश्यकता होती है

कॉलम और दीवारें: ऊर्ध्वाधर लोड अभिविन्यास के कारण समर्थन पहले ही हटाए जा सकते हैं

2.5 संरचनात्मक तत्व का आकार और डिज़ाइन

पूर्व-हटाने निरीक्षण चेकलिस्ट

समर्थन हटाने शुरू करने से पहले, एक व्यापक साइट निरीक्षण अनिवार्य है।

3.1 संरचनात्मक मूल्यांकन

दृश्यमान दरारों की जाँच करें

संरेखण और स्तर की पुष्टि करें

लोड पथ और वितरण की जाँच करें

3.2 कंक्रीट शक्ति परीक्षण

प्रयोगशाला नमूनों से घन या सिलेंडर शक्ति परीक्षण करें

त्वरित, गैर-विनाशकारी परीक्षण (NDT) के लिए साइट पर रिबाउंड हथौड़ा या अल्ट्रासोनिक पल्स वेलोसिटी परीक्षण का उपयोग करें

3.3 संरचनात्मक चित्र और विनिर्देशों की समीक्षा करें

IS 456:2000 या अन्य प्रासंगिक कोड देखें

संरचनात्मक सलाहकारों से न्यूनतम इलाज समय और समर्थन हटाने की सिफारिशों की क्रॉस-चेक करें

3.4 लोड पुनर्वितरण जाँच

किसी भी समर्थन को हटाने से पहले, जाँच करें कि संरचना बिना किसी विफलता के भार को पुनर्वितरित कर सकती है।

4. संचार और सुरक्षा योजना

समर्थन हटाना एक जोखिम भरा कार्य है जिसके लिए स्पष्ट संचार और सुरक्षा प्रोटोकॉल की आवश्यकता होती है।

4.1 टीम ब्रीफिंग

हटाने से पहले की बैठकें आयोजित करें

भूमिकाएँ और ज़िम्मेदारियाँ परिभाषित करें

आपातकालीन प्रक्रियाओं पर प्रकाश डालें

4.2 जोखिम मूल्यांकन

नौकरी जोखिम विश्लेषण (JHA) या जोखिम मूल्यांकन विधि विवरण (RAMS) तैयार करें

गिरने के जोखिम, ढहने के खतरे और उपकरण सुरक्षा चिंताओं की पहचान करें

4.3 व्यक्तिगत सुरक्षा उपकरण (PPE)

सुनिश्चित करें कि सभी कर्मचारी ये पहनें:

हेलमेट

सुरक्षा हार्नेस (यदि ऊँचाई पर काम कर रहे हैं)

दस्ताने

स्टील-टो बूट

आँखों की सुरक्षा (धूल से)

4.4 उपकरण और उपकरण जाँच

सुनिश्चित करें कि उठाने वाले उपकरण, जैक या यांत्रिक उपकरण अच्छी स्थिति में हैं

मचान और काम करने वाले प्लेटफ़ॉर्म का निरीक्षण करें

5. सुरक्षित समर्थन हटाने के लिए चरण-दर-चरण प्रक्रिया

निम्नलिखित प्रक्रियात्मक चरण सटीक और सुरक्षित कंक्रीट समर्थन हटाने के लिए एक व्यवस्थित दृष्टिकोण प्रदान करते हैं।

चरण 1: स्ट्रक्चरल इंजीनियर से स्वीकृति प्राप्त करें

लिखित स्वीकृति के बिना कोई भी समर्थन नहीं हटाया जाना चाहिए।

चरण 2: हटाने की प्रक्रिया को अनुक्रमित करें

आधार को निर्माण के विपरीत क्रम में हटाया जाना चाहिए, जो कि अंतिम रखे गए तत्व से शुरू होता है।

उदाहरण के लिए:

स्लैब → बीम → गर्डर्स → कॉलम → नींव

चरण 3: आंशिक स्ट्रिपिंग

शुरुआत में केवल गैर-भार वहन करने वाले तत्वों जैसे कि साइड फॉर्म को हटाएँ।

धीरे-धीरे मुख्य भार वहन करने वाले समर्थन को हटाएँ।

यदि आवश्यक हो तो बैक-प्रोपिंग को बनाए रखें।

चरण 4: विक्षेपण और गति की निगरानी करें

किसी भी तत्काल शिथिलता या मिसलिग्न्मेंट को मापने के लिए विक्षेपण गेज और लेजर स्तरों का उपयोग करें।

चरण 5: क्रमिक भार स्थानांतरण

यदि यांत्रिक सहारे का उपयोग किया जाता है, तो उन्हें क्रमिक रूप से कम करें ताकि कंक्रीट पर क्रमिक भार स्थानांतरण हो सके।

चरण 6: हटाने के बाद निरीक्षण

एक बार जब सपोर्ट पूरी तरह से हटा दिए जाते हैं:

सतह की गुणवत्ता की जाँच करें

दरारें, छत्ते या विक्षेपण के लिए निरीक्षण करें

साइट इंजीनियर को रिपोर्ट करें

6. सपोर्ट हटाने के लिए अनुशंसित समय-सीमा (सामान्य दिशानिर्देश)

जबकि वास्तविक हटाने का समय साइट की स्थितियों पर निर्भर करता है, निम्न तालिका सामान्य दिशानिर्देश प्रदान करती है (आईएस 456:2000 और एसीआई 347आर पर आधारित):

समर्थन हटाने से पहले संरचनात्मक सदस्य का न्यूनतम समय

बीम और स्तंभों के ऊर्ध्वाधर पक्ष 16-24 घंटे

स्लैब सॉफिट (बने रहने के लिए प्रॉप्स) 3 दिन

बीम सॉफिट (बने रहने के लिए प्रॉप्स) 7 दिन

स्लैब के लिए प्रॉप्स (4.5 मीटर स्पैन से कम) 7 दिन

स्लैब के लिए प्रॉप्स (4.5 मीटर स्पैन से अधिक) 14 दिन

बीम के लिए प्रॉप्स (6 मीटर स्पैन तक) 14 दिन

बीम के लिए प्रॉप्स (6 मीटर स्पैन से अधिक) 21 दिन

नोट: ये केवल सांकेतिक हैं। वास्तविक समय-सीमा को साइट-विशिष्ट संरचनात्मक इंजीनियर की सिफारिशों का पालन करना चाहिए।

7. उन्नत निगरानी तकनीक

महत्वपूर्ण संरचनाओं के लिए, समर्थन हटाने के दौरान सुरक्षा बढ़ाने के लिए उन्नत तकनीकों को अपनाएँ।

7.1 एम्बेडेड सेंसर

कंक्रीट में वास्तविक समय के तनाव और तनाव को मापें

यदि लोड थ्रेसहोल्ड पार हो जाता है तो अलर्ट प्रदान करें

7.2 प्रॉप्स पर लोड सेल

प्रत्येक प्रॉप द्वारा उठाए जा रहे सटीक लोड को मापें

असमान लोड वितरण का पता लगाएँ

7.3 ड्रोन और लेजर स्कैनिंग

दरार या विक्षेपण के लिए बड़े क्षेत्रों की निगरानी करें

डेटा संग्रह की गति और सटीकता में सुधार करें

8. मशीन सपोर्ट हटाने के दौरान बचने के लिए सामान्य गलतियाँ

8.1 शक्ति परीक्षण परिणामों की अनदेखी करना

कंक्रीट की ताकत की पुष्टि किए बिना केवल इसलिए हटाना जारी रखना कि "काफी दिन बीत चुके हैं" खतरनाक है।

8.2 बहुत जल्दी समर्थन हटाना

तेजी से हटाने से अचानक लोड ट्रांसफर होता है, जिससे दरारें या ढह जाती हैं।

8.3 संचार की कमी

साइट पर सभी टीमों को सूचित करने में विफलता दुर्घटनाओं का कारण बन सकती है। 8.4 हटाने के तुरंत बाद संरचना पर अधिक भार डालना ईंटवर्क, विभाजन या भंडारण सामग्री जैसे निर्माण भार रखने से पहले पर्याप्त समय दें। 8.5 गैर-अनुक्रमिक निष्कासन बेतरतीब ढंग से समर्थन हटाने से लोड पथ बाधित होते हैं और स्थिरता से समझौता होता है। 9. समर्थन हटाने की विफलताओं के मामले का अध्ययन पिछली विफलताओं को समझना सटीक तैयारी के महत्व को पुष्ट कर सकता है। केस 1: समय से पहले समर्थन हटाने के कारण पुल ढह गया 2018 में, एक महानगरीय शहर में एक पैदल यात्री पुल ढह गया क्योंकि कंक्रीट के डिजाइन की ताकत तक पहुँचने से पहले अस्थायी समर्थन हटा दिए गए थे। जाँच में पता चला: अपर्याप्त शक्ति परीक्षण कोई इंजीनियरिंग मंजूरी नहीं श्रमिक प्रशिक्षण की कमी

केस 2 एक ऊंची इमारत में फॉर्मवर्क को समय से पहले हटाने और ऊपर रखे गए ओवरलोडेड उपकरणों के कारण आंशिक रूप से स्लैब ढह गया। यह हटाने के बाद लोड नियंत्रण की आवश्यकता को उजागर करता है।

10. दीर्घकालिक सुरक्षा के लिए सर्वोत्तम अभ्यास

हर चरण का दस्तावेजीकरण करें: हटाने की तिथियों, शक्ति परीक्षण परिणामों और इंजीनियर अनुमोदनों का विस्तृत रिकॉर्ड रखें।

श्रमिकों को प्रशिक्षित करें: फॉर्मवर्क निर्माण और हटाने की प्रक्रियाओं पर समय-समय पर प्रशिक्षण सत्र आयोजित करें।

प्रौद्योगिकी का उपयोग करें: बड़ी परियोजनाओं के लिए आधुनिक निगरानी प्रणाली अपनाएं।

विशेषज्ञों को शामिल करें: महत्वपूर्ण निर्णय लेने से पहले हमेशा संरचनात्मक इंजीनियरों से परामर्श करें।

निष्कर्ष

कंक्रीट मशीन समर्थन हटाना केवल अस्थायी संरचनाओं को हटाने से कहीं अधिक है। यह एक अत्यधिक तकनीकी और जोखिम-संवेदनशील प्रक्रिया है जो योजना, परीक्षण, संचार और सख्त पर्यवेक्षण की मांग करती है।

ऊपर बताए गए दिशा-निर्देशों का पालन करके, निर्माण दल यह सुनिश्चित कर सकते हैं:

कार्यकर्ता सुरक्षा

संरचनात्मक अखंडता

इंजीनियरिंग मानकों का अनुपालन

प्रोजेक्ट की समयसीमा और बजट बरकरार रहे

आखिरकार, मशीन सपोर्ट हटाने की तैयारी में सटीकता सफल कंक्रीट निर्माण का एक महत्वपूर्ण स्तंभ है।

आपकी YouTube स्क्रिप्ट के लिए चैनल शाउटआउट:

"सिविल इंजीनियरिंग और साइट सुरक्षा प्रथाओं पर अधिक विशेषज्ञ युक्तियों के लिए, इंजीनियर्स इंडिया सॉल्यूशन को लाइक, शेयर और सब्सक्राइब करना न भूलें! वास्तविक दुनिया के निर्माण स्थल के ज्ञान और इंजीनियरिंग अंतर्दृष्टि के लिए बने रहें!"