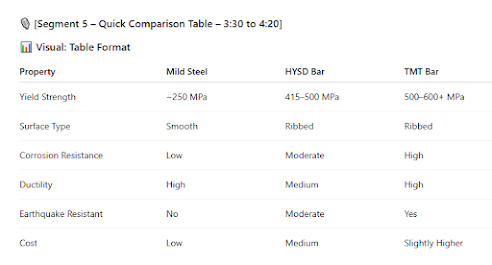

**TMT vs HYSD vs MS steel bars**, ideal # 🏗️ **TMT vs HYSD vs MS Steel Bars – Which Is Best for Construction?** ## 🔶 1. **MS (Mild Steel) Bars** **Full Form:** Mild Steel Bars **Standard Grade:** Fe 250 ### ✅ Features: * **Plain surface**, no ribs * Low tensile strength: **250 N/mm²** * **Ductile** and easy to bend * Used mainly in **structural members** where no high tension is involved ### ❌ Limitations: * No bond strength with concrete * Prone to corrosion * Not ideal for modern RCC structures ## 🔶 2. **HYSD High Yield Strength Deformed Bars** **Full Form:** High Yield Strength Deformed Bars **Common Grades:** Fe 415, Fe 500 ### ✅ Features: * Deformed with **ribs and lugs** for strong bonding * Higher tensile strength: **415–500 N/mm²** * Used extensively in RCC structures * Cost-effective and stronger than MS bars ### ❌ Limitations: * Higher carbon content → slightly less ductile * Prone to corrosion in aggressive environments ## 🔶 3. **TMT Thermo Mechanically Treated Bars** **Full Form:** Thermo Mechanically Treated Bars **Common Grades:** Fe 500, Fe 550, Fe 600 ### ✅ Features: * Manufactured using **quenching and tempering** process * **Tough outer core**, soft inner core → Excellent **ductility + strength** * Superior **corrosion resistance** * High earthquake resistance * Weldable, bendable, and **better bonding** with concrete ### ❌ Limitations: * Slightly costlier than HYSD ## 🔍 **Comparison Table:** | Property | MS Bars | HYSD Bars | TMT Bars | | ---------------- ----- | ---- --- | ------- - --- | ------ --------------- | | Strength (N/mm²) | \~250 | 415–500 | 500–600 | | Surface | Plain | Deformed | Ribbed & toughened | | Corrosion Resistance | ❌ Poor | ❌ Moderate | ✅ Excellent | | Ductility | ✅ High | Moderate | ✅ Very High | | Earthquake Resistance | ❌ Low | ❌ Moderate | ✅ Excellent | | Cost | 💲 Low | 💲💲 Medium | 💲💲💲 Slightly Higher | ## 🏆 **Conclusion: Which is Best?** ### 🔹 For **modern RCC structures**, **TMT bars are the best** due to: * High strength * Corrosion resistance * Earthquake resilience * Longevity and safety 🛑 **MS bars** are outdated and only used for temporary or minor works. ✅ **HYSD** is still used but **TMT** has replaced it in most large-scale projects due to its superior performance. ## 🎯 Final Verdict: 🔨 **TMT Bars Fe 500 or Fe 550** are the best steel bars for any civil construction — safe, strong, and built for the future.

I AM A CIVIL ENGINEER AND TEACHING FOR THE PAST 34 YEARS AS OF NOW AND AM SHARING MY EXPERIENCE'S RIGHT FROM THE BEGINNING AS A ENGINEERING STUDENT WITH MAINLY EDUCATIONAL SUBJECTS RELATED TO CIVIL ENGINEERING THE MAIN MOTIVE IS TO KEEP THE PRACTICAL ASPECT CLEAR and moving for civil engineers RECENTLY I HAVE TAKEN OTHER SUBJECTS TOO LIKE CHEMISTRY WORKSHOP TECHNOLOGY etc

About Me YOU THINK I WILL DO IT

- @Engineers India Solutions

- I AM A CIVIL ENGINEERING BY PROFESSION '34 YEAR'S OF EXPERIENCE PROVIDING PRACTICAL AND FIELD KNOWLEDGE ' MOSTLY FIELD WORK CRAZE FOR CIVIL WORK OR SAY ONSITE WORKhttps://engineersindiasolutions.wordpress.com/ WEBSITE

Sunday, 27 July 2025

**TMT vs HYSD vs MS steel bars**,

**TMT vs HYSD vs MS steel bars**, ideal # 🏗️ **TMT vs HYSD vs MS Steel Bars – Which Is Best for Construction?** ## 🔶 1. **MS (Mild Steel) Bars** **Full Form:** Mild Steel Bars **Standard Grade:** Fe 250 ### ✅ Features: * **Plain surface**, no ribs * Low tensile strength: **250 N/mm²** * **Ductile** and easy to bend * Used mainly in **structural members** where no high tension is involved ### ❌ Limitations: * No bond strength with concrete * Prone to corrosion * Not ideal for modern RCC structures ## 🔶 2. **HYSD High Yield Strength Deformed Bars** **Full Form:** High Yield Strength Deformed Bars **Common Grades:** Fe 415, Fe 500 ### ✅ Features: * Deformed with **ribs and lugs** for strong bonding * Higher tensile strength: **415–500 N/mm²** * Used extensively in RCC structures * Cost-effective and stronger than MS bars ### ❌ Limitations: * Higher carbon content → slightly less ductile * Prone to corrosion in aggressive environments ## 🔶 3. **TMT Thermo Mechanically Treated Bars** **Full Form:** Thermo Mechanically Treated Bars **Common Grades:** Fe 500, Fe 550, Fe 600 ### ✅ Features: * Manufactured using **quenching and tempering** process * **Tough outer core**, soft inner core → Excellent **ductility + strength** * Superior **corrosion resistance** * High earthquake resistance * Weldable, bendable, and **better bonding** with concrete ### ❌ Limitations: * Slightly costlier than HYSD ## 🔍 **Comparison Table:** | Property | MS Bars | HYSD Bars | TMT Bars | | ---------------- ----- | ---- --- | ------- - --- | ------ --------------- | | Strength (N/mm²) | \~250 | 415–500 | 500–600 | | Surface | Plain | Deformed | Ribbed & toughened | | Corrosion Resistance | ❌ Poor | ❌ Moderate | ✅ Excellent | | Ductility | ✅ High | Moderate | ✅ Very High | | Earthquake Resistance | ❌ Low | ❌ Moderate | ✅ Excellent | | Cost | 💲 Low | 💲💲 Medium | 💲💲💲 Slightly Higher | ## 🏆 **Conclusion: Which is Best?** ### 🔹 For **modern RCC structures**, **TMT bars are the best** due to: * High strength * Corrosion resistance * Earthquake resilience * Longevity and safety 🛑 **MS bars** are outdated and only used for temporary or minor works. ✅ **HYSD** is still used but **TMT** has replaced it in most large-scale projects due to its superior performance. ## 🎯 Final Verdict: 🔨 **TMT Bars Fe 500 or Fe 550** are the best steel bars for any civil construction — safe, strong, and built for the future.

Subscribe to:

Post Comments (Atom)

# **Dams – Types, Construction, and Importance**

## **1. Introduction** A dam is one of the most remarkable feats of civil engineering. It represents humanity’s ability to harness natura...

-

Here is a concise and complete summary of Water Quality Requirements as per IS:456:2000 , useful for notes, teaching, or video content. ...

-

video links S P T Test PROCEDURE BY MECHANICAL METHOD SHORTS https://youtu.be/eVFFP7Q6uvw COMPATION O...

-

In **prismatic surveying**, **fore bearing (FB)** and **back bearing (BB)** are essential for determining the direction of a survey line. T...

No comments:

Post a Comment